Blog

A basic guide to choosing the style of counterbore plate

Here is a basic guide to choosing what style counterbore plate you need for the counterbore shim cutter and the counterbore sleeving tool. This should be easier than it seems to be.

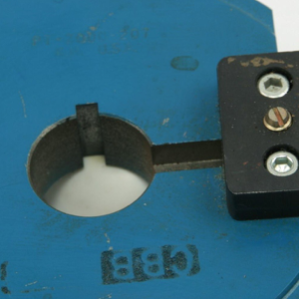

If your tool looks like this, the T-handle is the easiest clue. This is the Porta-Tool - Kent-Moore Shim Cutter. It will be usually blue or green.

Above is the Apex – Monaco shim cutter.

Both the Porta-Tool and Apex counterbore shim cutters use the same screw on cutter plates. If your counterbore tool is black and has the T handle but the plate is fitted on a tapered shaft, look at the name plate - if it says BK Sweeney, then beg the owner for some money because this tool has been obsolete since bell bottoms were still in style.

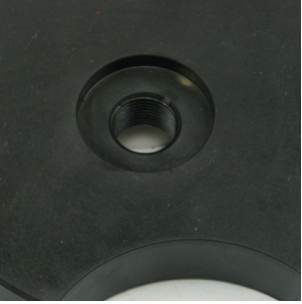

The plates that go on this tool will look like this in the center. If it does not have threads it will not fit this tool.

This tool above is intended to install counterbore shims. It was never intended to install sleeves and can not be made to cut them as a poor man's sleeving tool.

Above is an original model Porta-Tool counterbore sleeving tool. It can come in blue or green. It will always have a depth collar and the drive off to the side. It may have a ball or a flat plate. It will only have one depth collar.

This is a modern counterbore sleeving tool. It will be blue with a wrap around handle and the feed control is on the front. It will have the same depth collar and drive as the original tool.

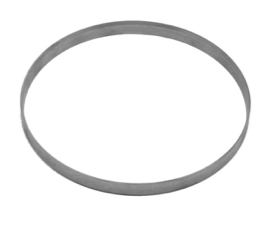

Both the original and modern counterbore sleeving tool use the same bolt on plates.

All your Porta-Tool - Kent-Moore counterbore sleeving tools will use a plate that slides on with a key way. If your plate does not look like this (above) it will not fit this tool.

The top deck sleeving, shown above, is intended to remove a large amount of block material rapidly. The tool was designed to install sleeves in the top counterbore region on diesel engines. It was never meant to do both sleeving and shim cutting. A new tool out of the box will have a 5 thousands variation on depth of cutting. This will grow larger with some wear. I have known some very talented mobile machining guys that use this tool for everything but the key to this is they have a tool for every job and nobody touches their tools. They also make their money by speed and volume so little mistakes are something they know how to field fix.

I didn’t cover the mid-stop counterbore engines in this blog post but they are easy. All the tools have a T-Handle and they do not make a sleeving tool plate for these engines. So this is pretty easy. But unfortunately the mid-stop and ISX are different tools, sorry.

I know this is a basically simple blog and to most, this is old hat. Unfortunately we are getting calls everyday confused on what they can do with their tools. If I asked my order department what they would want to convey, it would be that you can not put the 60 series sleeve cutting plate on the shim cutter nor can this tool cut sleeves on a 60 series.

As always happy wrenching!

-- Fred