Blog

Counterbore Tools

The counterboring process usually involves making a cavity of the size and thickness of the head of the fastener, allowing the fastener to remain completely below the surface level of the workpiece. Typical tools for counterboring involve special drills that have two different cutting diameters – one to make the hole for the fastener body and the other, of a larger diameter, for making the cavity for the head of the fastener.

Flat-bottomed counterbore drills are used where the surface is irregular or there is need for spot facing. Typically, these flat-bottomed counterbore drills are a no-dish design, ideal for drafted or concaved surfaces, rounded parts and castings. These drills are useful for straightening misaligned holes or for a process that requires flat bottom reaming. Usually made of solid Carbide, the counterbore drills have four flutes with a 15 helix. The cutter diameter, flute length, shank diameter and overall length of the flat bottomed counterbore drill depends on the type of application and the user must select the tool from a chart offered by the manufacturer.

Not all counterbores involve fasteners. For example, diesel engine blocks often need counterboring when repairing them. Usually, the engine block and wet liners develop a leak and the counterbore seats in the engine block need to be resurfaced during an engine overhaul. This requires counterbore cutter plates and a very accurate counterbore-machining unit that can be centered automatically and be clamped by means of an electromagnet. Since the technicians place the machine directly on the sealing surface of the engine block under repair, the refaced counterbore seats are automatically aligned in parallel to the sealing surface. Usually, these counterboring machines are portable types, allowing them to be used for refacing procedures not only on installed engines but also removed engine blocks or on underfloor engines as well.

For making counterbore cavities of large diameters, it is customary to use blade type counterbores. The blade material is generally high speed steel and the size of the blade must be chosen for the application. The blade fastens to the shank by socket-head cap screw. Two types of blades are available, one for forward cutting and the other for backward.

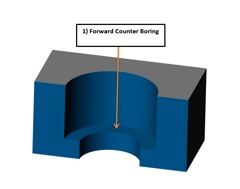

The forward counterbore cutting blades are plunge style tools meant for use on predrilled holes. You can use these tools on a manual mill as well as on a CNC milling machine. Used on a manual or a CNC lathe, a forward counterbore may also be used for a profile bore or a plunge bore on almost all types of metals.

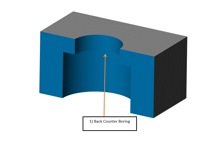

The back counterbore, or back spot facer as it is commonly known, is a versatile tool intended to go through a pre-bored hole to produce a counterbore on the backside of the hole. You can use the back counterbore tool in a lathe setting for profiling an ID in a hole. Usually, a through-hole in the tool provides means to supply coolant to the cutting edge. Back counterbore tools are used in a variety of industries such as automotive and valve industries for numerous materials.

★★★★★

★★★★★

★★★★★